Researchers have created a polymer “Chinese lantern” that can snap into more than a dozen curved, three-dimensional shapes by compressing or twisting the original structure. This rapid shape-shifting behavior can be controlled remotely using a magnetic field, allowing the structure to be used for a variety of applications. Credit: Yaoye Hong, NC State University

Researchers have developed a polymer structure inspired by a classic “Chinese lantern” that can change into more than a dozen curved, three-dimensional shapes when it is compressed or twisted. These quick shape transitions can also be triggered remotely with a magnetic field, which makes the design suitable for many potential uses.

How the Lantern Structure Is Built

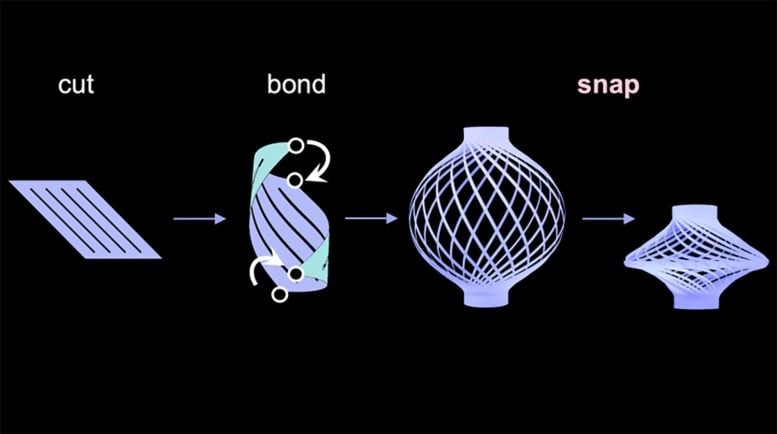

To create the lantern, the team began with a thin polymer sheet cut into the shape of a diamond-like parallelogram. They then added a row of evenly spaced cuts across the middle of the sheet, producing parallel ribbons held together at the top and bottom by solid strips of material. When the ends of these top and bottom strips are joined, the sheet bends outward and takes on a rounded, lantern-like form.

A Bistable Design With Stored Energy

“This basic shape is, by itself, bistable,” says Jie Yin, corresponding author of the work and a professor of mechanical and aerospace engineering at North Carolina State University. “In other words, it has two stable forms. It is stable in its lantern shape, of course. But if you compress the structure, pushing down from the top, it will slowly begin to deform until it reaches a critical point, at which point it snaps into a second stable shape that resembles a spinning top.

In the spinning-top shape, the structure has stored all of the energy you used to compress it. So, once you begin to pull up on the structure, you will reach a point where all of that energy is released at once, causing it to snap back into the lantern shape very quickly.”

The basic lantern object is made by cutting a polymer sheet into a diamond-like parallelogram shape, then cutting a row of parallel lines across the center of each sheet. This creates a row of identical ribbons that is connected by a solid strip of material at the top and bottom of the sheet. By connecting the left and right ends of the solid strips at top and bottom, the polymer sheet forms a three-dimensional shape resembling a roughly spherical Chinese lantern.

Credit: Yaoye Hong, NC State University

Twisting, Folding, and Multistable Variations

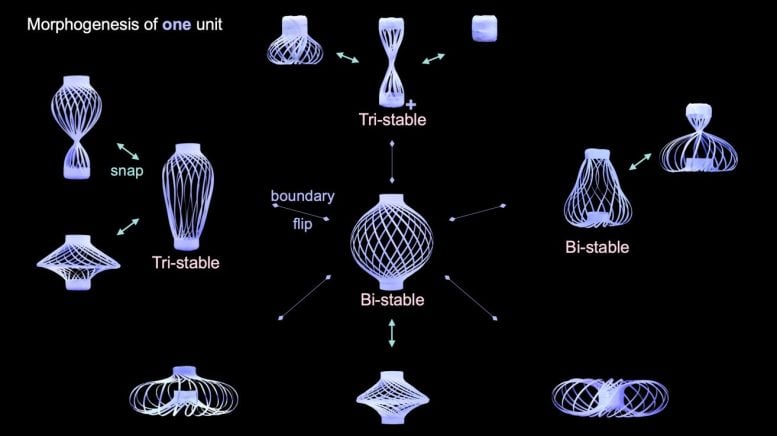

According to Yaoye Hong, first author of the paper and a former Ph.D. student at NC State who is now a postdoctoral researcher at the University of Pennsylvania, the team discovered that the lantern can be reshaped in many ways beyond simple compression.

“We found that we could create many additional shapes by applying a twist to the shape, by folding the solid strips at the top or bottom of the lantern in or out, or any combination of those things,” Hong says. “Each of these variations is also multistable. Some can snap back and forth between two stable states. One has four stable states, depending on whether you’re compressing the structure, twisting the structure, or compressing and twisting the structure simultaneously.”

Remote Control and Real-World Demonstrations

The researchers also enhanced the structure by placing a thin magnetic film on the bottom strip of the lantern. This allowed them to twist or compress the design from a distance using a magnetic field. Several examples were demonstrated, including a gentle gripper that could hold a fish without injury, a water filter that opened and closed to manage flow, and a compact configuration that suddenly extended upward to reopen a collapsed tube.

Modeling Stability, Shape, and Energy Storage

To better understand how each version of the lantern behaves, the team developed a mathematical model that describes how the geometry of the structure influences its shape and the amount of elastic energy stored in each stable state.

“This model allows us to program the shape we want to create, how stable it is, and how powerful it can be when stored potential energy is allowed to snap into kinetic energy,” says Hong. “And all of those things are critical for creating shapes that can perform desired applications.”

Toward Future Metamaterials and Robotics

“Moving forward, these lantern units can be assembled into 2D and 3D architectures for broad applications in shape-morphing mechanical metamaterials and robotics,” says Yin. “We will be exploring that.”

Reference: “Reprogrammable snapping morphogenesis in ribbon-cluster meta-units using stored elastic energy” by Yaoye Hong, Caizhi Zhou, Haitao Qing, Yinding Chi and Jie Yin, 10 October 2025, Nature Materials.

DOI: 10.1038/s41563-025-02370-z

The paper was co-authored by Caizhi Zhou and Haitao Qing, both Ph.D. students at NC State; and by Yinding Chi, a former Ph.D. student at NC State who is now a postdoctoral researcher at Penn.

This work was done with support from the National Science Foundation under grants 2005374, 2369274 and 2445551.

Never miss a breakthrough: Join the SciTechDaily newsletter.

Follow us on Google and Google News.

Comments(0)

Join the conversation and share your perspective.

Sign In to Comment